Innovation

We develop what protects tomorrow - today.

Lightness that creates buoyancy

More than connected - structurally united.

Metal foam rethought - integrative connectedunique stable.

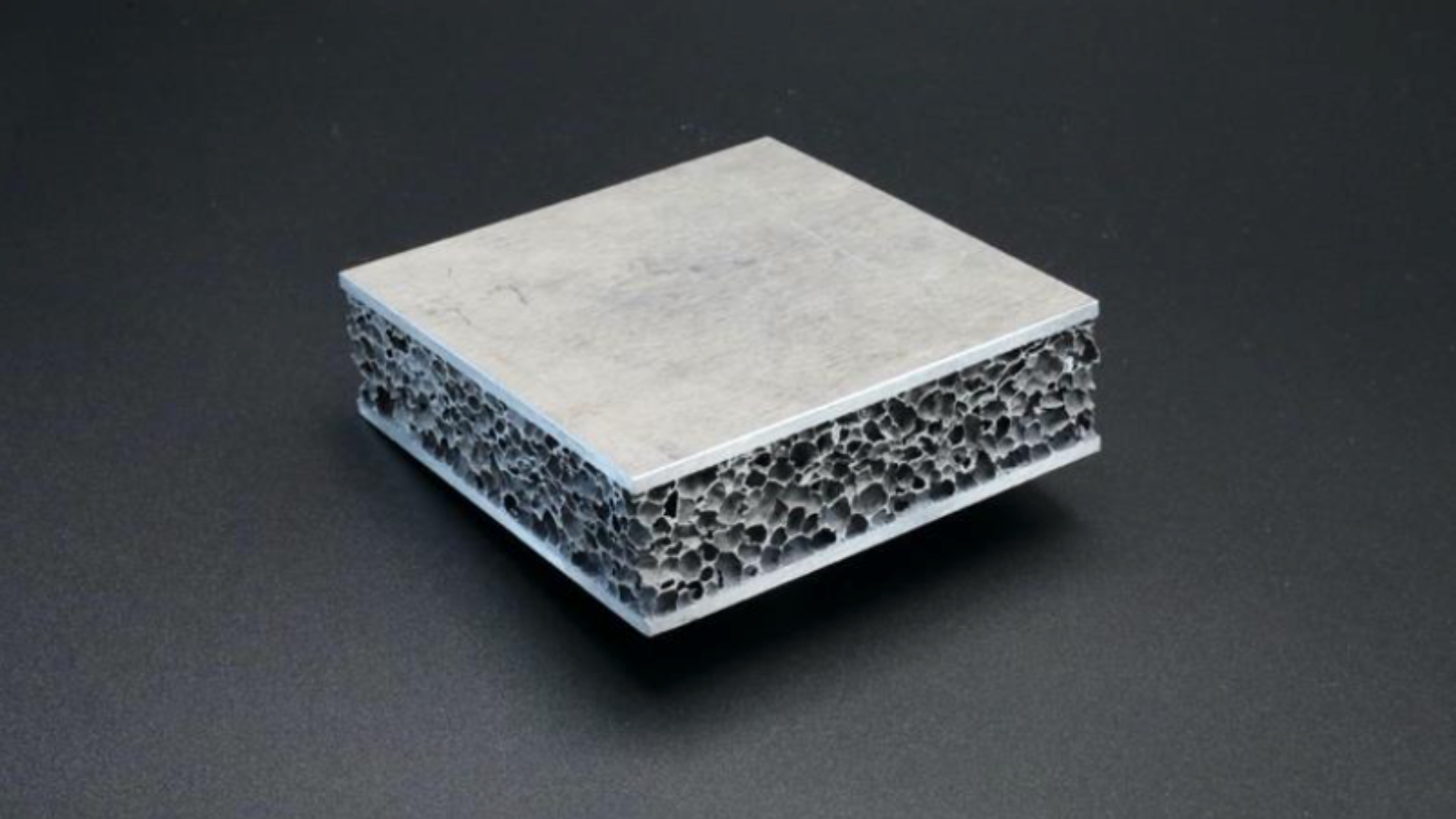

What International Metal Foam AG develops with its partners cannot simply be replicated - because our metal foam is more than just a material: it becomes a functional component of the entire structure. Thanks to our specially developed process, the foam is connected to the cover panels in a form-fitting manner - to form a continuous unit with no joints, no adhesive and no weak points. This structural connection with the cover panels creates a single material body - not a combination of individual components.

The result is a material with exceptional mechanical strength, high energy absorption and low weight. We develop solutions that do not have to adapt - but are already designed for use.

- Structural unity instead of glued weak points

- Technological edge through ongoing development

- Diversity through precision

Technologythat connects

A structure that can do more than just support.

Metal foamwell thought out down to the last detail Detail - from the inside out.

What looks compact on the outside is highly complex on the inside. The three-dimensional cell structure of the metal foam is not a filling material - it is the functional core. Every cavity, every connection follows a clear principle: absorbing, distributing and defusing energy. Vibrations, impact forces or extreme temperature differences - all this is absorbed on the inside before it reaches the outside. In conjunction with the cover panels, this creates a system that not only protects, but also thinks for itself. Stable, light, reliable - even under conditions where others fail.

Security that keeps you afloat.

For Applicationswhere weight, stability and Buoyancy are decisive.

What a cross-section reveals is often decisive. With IMF, it shows one thing above all: absolute continuity. No separation between foam and panel, no glued surface - but a continuous, friction-locked transition where every detail fits. This solid connection is not just a technical advantage - it is a promise of safety. Because where other systems come loose, this structure remains stable. Even after years. Even in an emergency. And this is precisely what makes our material unique: it doesn't just hold together. It delivers what it promises.

- Closed cell structure prevents water absorption even during long-term use.

- Optimum ratio of weight, stability and buoyancy - ideal for transportation and construction.

- Lower tare weight enables more payload with lower energy consumption.

Metal foam in detail

A material whose structure is more than just technology - it is a principle.

Versatile and scalable

Structurally connected

Modular use

Dynamic damping

Molded for every challenge. Developed for use.

Over 750 different molded parts are planned for the future. International Metal Foam AG will thus offer a product range designed for a wide variety of applications - from ballistic protection to structural lightweight elements and electromagnetic shielding. Each part has a clear function: protection, stability, integration.

Our components are not only manufactured in series, but also newly developed and certified in close cooperation with our partners if required. This results in solutions that do not have to be adapted - but are designed for use from the outset. Flexible in format, reliable in effect.

Verdal / Civil applications

The Verdal product line stands for versatile lightweight construction solutions in the civil sector. Whether medical devices, vehicle components or protective shields for critical infrastructures - the various foam formulations have been specially developed for urban use and industrial requirements. They combine high dimensional stability with complete recyclability and open up new possibilities for sustainable product architecture.

Defdral / Military applications

Defdral is the answer to complex threat scenarios. The product line was developed for use in ballistic protection systems, helmets, vehicle armor and maritime components. The unique structure of the metal foam offers effective protection against bullets, explosions and splinters - while keeping weight to a minimum. This results in solutions that save lives and keep systems functional.

Diversity with a system. Effect with precision.

Our metal foam solutions adapt to the requirements - not the other way around. Whether infrastructure, mobility or protection systems: every application starts with the right material.

Structural lightness for vehicles, trains and systems with reach.

Robust molded parts for energy, transport and communication networks.

Personal protection with a system - vests, helmets and modular solutions.

Floating and corrosion-resistant components - from yachts to coastal protection.

Systems that build on each other

Flexible technology. Integration with a system.

Technologythat are integrated into existing Systems fits.

Our metal foam is not tied to one plant, but to one principle: simple integration into existing production processes. Together with our partner company Xerionwhich provides specially developed blast furnaces, we create modular production solutions that can be used worldwide. In combination with customizable recipes, production is scalable, efficient and possible directly on site. This means that our protection systems can not only be provided more quickly, but also manufactured regionally - a decisive advantage for security of supply, time savings and industrial sovereignty.

Sharing technology. Anchoring responsibility.

A License modelthat creates more than access - namely Added value.

International Metal Foam AG grants licenses that go far beyond the right of use: Production licenses enable complete production in the customer's own country. Territory licenses expand regional markets. And customized cooperation models efficiently integrate existing infrastructure. The result? A resilient supply chain, economic independence - and a technology that is not exported, but arrives where it works.

Production on demand. Technology with scope.

Thanks to modular systems, flexible oven technology and customized recipes, the production approach is as scalable as your requirements. From test operation to national series production, every stage can be implemented in a targeted manner - efficiently, resiliently and with investment security.

Global technology that creates independence.

With independent production and a global partner network, a technology system is created that can act independently - technologically sovereign, internationally anchored and adaptable at any time.

Local independence & security of supply

Whether for defense, infrastructure or crisis protection: International Metal Foam AG creates systems that can be manufactured, maintained and further developed in their own country. This not only protects people and systems - but entire value chains.